News Release

7/8/2024

NORITAKE CO., LIMITED

Announcement of the development of porous support "SUPCA" for DAC

- enables efficient CO2 capture and environmentally friendly design with our exclusive technology -

NORITAKE CO., LIMITED (Headquarters: Nagoya, Aichi, Representative Director & President: Akira Higashiyama) has developed a porous support, SUPCA, for Direct Air Capture (DAC) to directly capture CO2 from the atmosphere. SUPCA retains CO2 absorption solution in its internal sorbent※1, allowing for the absorption, desorption, and recovery of CO2. Some of the raw materials used in SUPCA are biomass materials that are produced with reduced CO2 emissions.

■Background of the development

In the context of the growing demand for carbon neutrality, the efficiency of capturing CO2, which exists in the atmosphere at only 0.04%, is crucial in DAC technology. Therefore, materials for CO2 capture are required to have the ability to rapidly absorb CO2 and to process the atmosphere with low energy consumption by reducing pressure losses. Furthermore, conventional sorbents are mainly made from synthetic materials, which pose a challenge of high CO2 emissions during their manufacturing process.

■About “SUPCA”

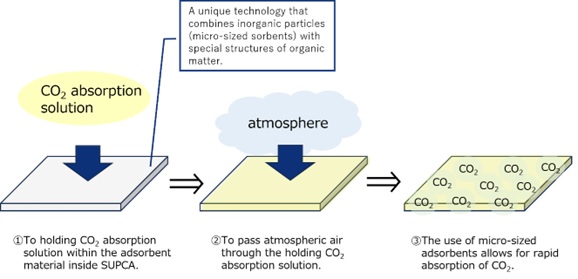

SUPCA is a product developed using our proprietary technology that combines inorganic particles (micro-sized sorbents) with organic matter having a special structure.The sorbent has a large surface area for contact with CO2, allowing for fast absorption. This enables efficient CO2 capture. Additionally, SUPCA incorporates biomass materials produced with reduced CO2 emissions as part of its raw materials. Moving forward, we will further promote the use of renewable materials and continue our development efforts towards environmental sustainability.

【Performance comparison between SUPCA and conventional products (bead-shaped sorbents)】

Table 1: Relative comparison of following two samples holding CO2 absorption solution that adsorb an equal amount of CO2.

① The reasons for fast absorption of CO2.

・The contact area between the sorbent and CO2 is large per unit volume.

・Due to the small diameter of the sorbent,CO2 quickly spreads throughout its interior.

② The reasons for low energy consumption.

The ease of gas flow※4 is 10 times higher compared to conventional products. The energy consumption during the process of blowing air and contacting it with SUPCA is low.

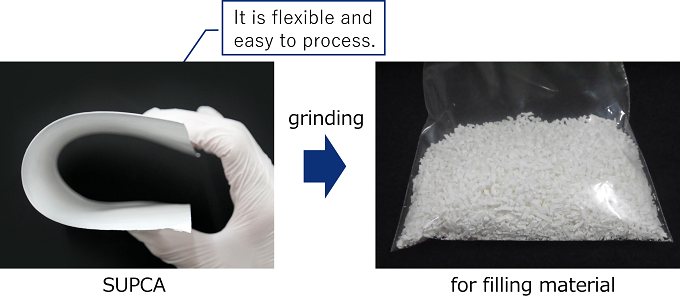

Furthermore, it offers high convenience and has a wide range of usage.

It is flexible and easy to process, allowing it to be used in various shapes.

■The mechanism by which SUPCA absorbs CO2.

※1 An sorbent that holds the CO2 absorption solution.

※2 Measurement conditions: The comparison is made based on the value of (CO2 saturation absorption amount) divided by (the time from the start of CO2 absorption to saturation) using an sorbent with the same saturated CO2 absorption capacity.

※3 Calculation of the total energy required for the entire process of CO2 absorption, desorption, and recovery by the equipment. (Calculation performed by system manufacturers.)

※4 Compare based on pressure loss. Pressure loss refers to the pressure lost as the fluid passes through a flow path. A lower pressure loss can be said to occur when the difference in total pressure between the inlet and outlet is small.

■Contact Information

NORITAKE CO., LIMITED Research & Development Center

E-mail:kaihatsu_b9700@noritake.com