PRODUCTS

Mesh Belt Kiln

- Technical Support

- Catalog Download

- About Our Sales Offices

Technical Support

Mesh Belt Kiln is a continuous firing furnace, conveying of products by metal mesh-belt conveyer.

It has excellent productivity at low temperature zone.

| Working temperature | R.T.~1000℃ |

|---|---|

| Temperature precision | ±2℃(at 1000℃) |

| Oxygen concentratio | ~10ppm |

| Atmosphere | N2、H2、O2、Ar |

Clean

Gas flow is controlled from firing zone to burnout zone and binder is exhausted outside of the kiln at an optimum temperature. This allows for maintaining of a clean atmosphere possible.

Highly Precise Temperature Distribution

Heater alignment is based on past record and separation control makes precise temperature distribution for any temperature range possible.

Energy-Saving

Kiln body, except muffle, is built with molded ceramic fiber and is saving energy structure, it can significantly reduce power consumption.

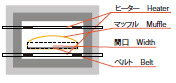

Furnace internal structure

Muffle type

| Muffle type | Non-Muffle type | |

|---|---|---|

| Structure |  |

|

| Heating method | Infrared secondary heating (Metal muffle) | Ceramic tube far-infrared direct heating |

| Power consumption | Large | Small (Energy-saving type) |

| Dust | A little | Nothing |

| Temperature homogeneity | High | Average (High in the width direction) |

| Temperature response | Low | High |

| Temperature control | SSR、SCR | SSR、SCR |

| Atmosphere | Air, Special atmosphere (~10ppm) | Air |